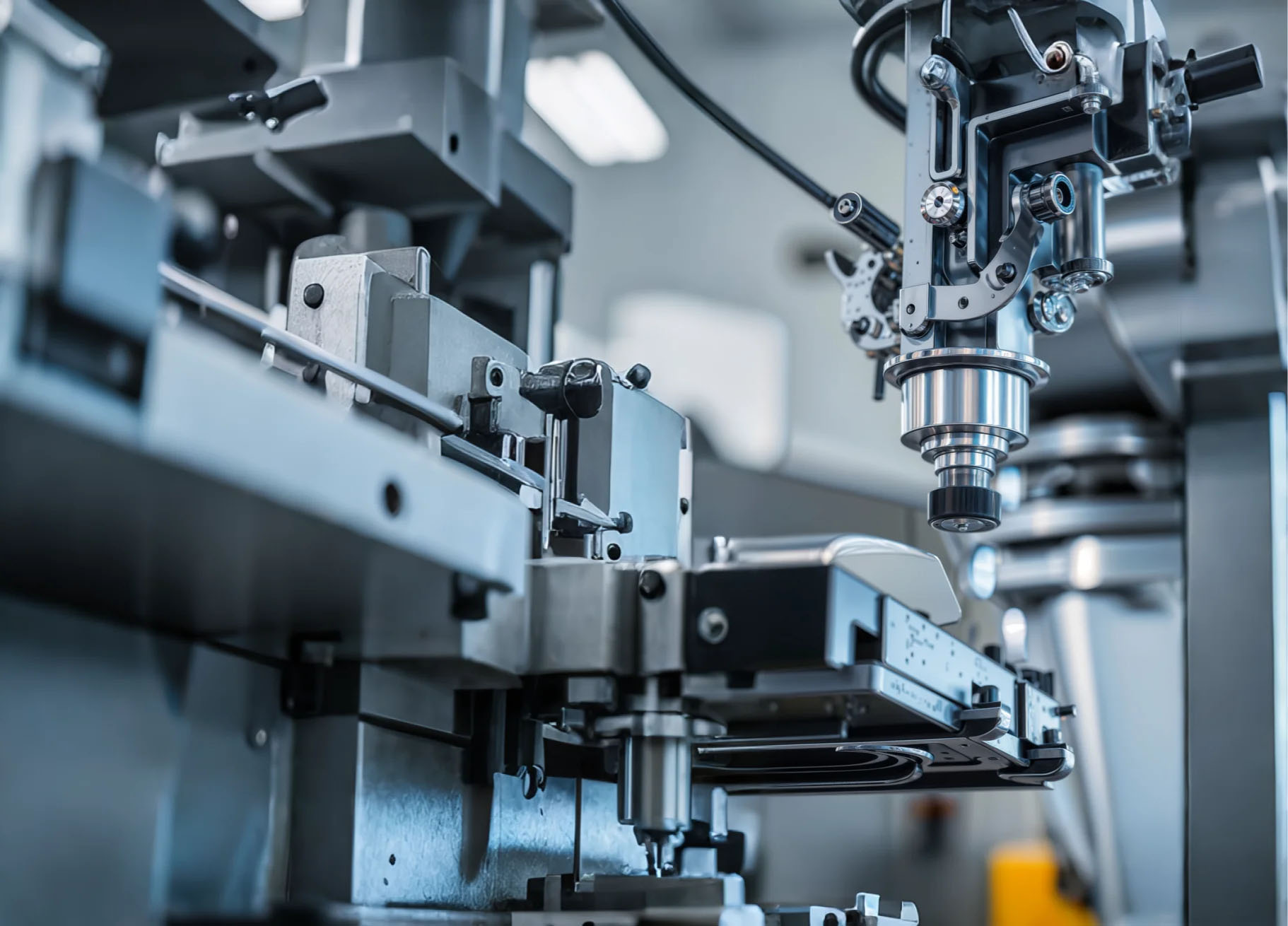

Advanced Endoscopic Camera Cable Welding: Precision Welding Solutions for Medical Device Manufacturing

December 1, 2025

In the modern minimally invasive medical field, endoscopic technology is continuously evolving towards smaller trauma, higher clarity, and stronger functionality. As the "eyes" of endoscopes, the manufacturing process of ultra-miniature cameras directly determines the performance of the equipment. Wire harness welding, as the core technology connecting ultra-miniature cameras to transmission systems, has become a critical link in medical device manufacturing.

Technical Challenges and Difficulties

Wire harness welding for endoscopic ultra-miniature cameras faces multiple challenges:

Extremely small size: The welding area is typically less than 0.5mm² and requires operation under a microscope.

Material diversity: Involves connections between various materials such as copper, gold, and stainless steel.

Extremely high reliability requirements: Medical devices must ensure long-term stability and safety.

High thermal sensitivity: Surrounding components are highly sensitive to temperature changes, requiring precise control of the heat-affected zone.

Advanced Welding Processes

Laser Micro-Welding Technology

Pulsed laser welding has become the preferred solution for ultra-miniature wire harness connections. By adjusting pulse energy, duration, and frequency, precise energy control can be achieved, minimizing the heat-affected zone. Our laser welding system can achieve:

Minimum weld spot diameter of 20μm.

Heat-affected zone controlled within 100μm.

Welding strength reaching over 85% of the material's inherent strength.

Gold Wire Ball Bonding Process

For particularly precise connection requirements, we employ gold wire ball bonding technology:

Uses 99.99% high-purity gold wire.

Welding temperature accurately controlled within a ±3°C range.

Enables reliable connections for wire diameters below 25μm.

Quality Control System

We have established a comprehensive quality assurance process:

Pre-weld cleaning: Utilizes plasma cleaning technology to ensure welding surfaces are free of oxides and contaminants.

Real-time monitoring: High-speed camera systems monitor the welding process in real time, automatically adjusting parameters.

Strength testing: Employs micro-tensile testers to verify the strength of each weld point.

Reliability inspection: Includes temperature cycle testing, vibration testing, and durability testing.

Technical Application Value

Through advanced ultra-miniature wire harness welding technology, we help clients achieve:

Endoscope diameter reduction to below 3mm, expanding clinical application scope.

Improved image transmission stability, reducing signal loss.

Extended device lifespan, lowering maintenance costs.

Enhanced surgical precision, providing patients with a safer diagnosis and treatment experience.

Conclusion

As minimally invasive surgical technology continues to develop, the performance requirements for endoscopes will keep increasing. We will continue to deepen our expertise in the ultra-miniature welding field, offering more reliable and precise connection solutions for medical device manufacturers through technological innovation and process optimization, jointly advancing medical technology progress.