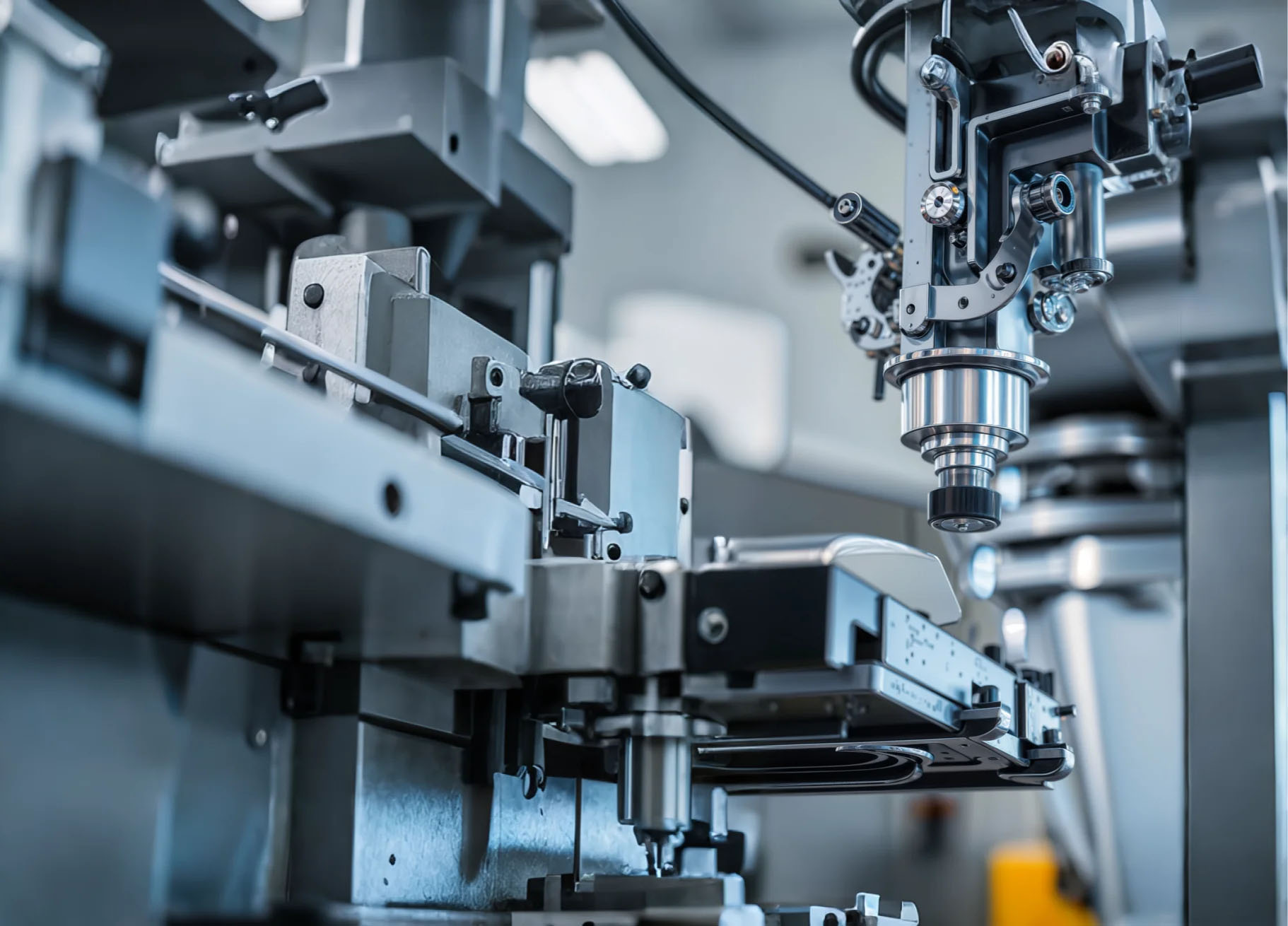

Snake bone riveting technology enables precise, reliable flexible endoscope manufacturing—enhancing flexibility, durability, and surgical outcomes.

Snake bone riveting technology enables precise, reliable flexible endoscope manufacturing—enhancing flexibility, durability, and surgical outcomes.

Advanced camera cable welding with laser micro-welding and gold wire bonding ensures medical-grade reliability. It enables smaller diameters, stable imaging, and better surgical performance in minimally invasive procedures.

Insertion tube fatigue testing ensures safety and reliability by simulating extreme bending and torsion over thousands of cycles, helping prevent failures and ensure compliance.

Endoscopic camera systems deliver high-definition surgical visualization through advanced sensors, optics, and AI—enhancing efficiency, safety, and minimally invasive precision.

Disposable endoscopes are not a simple replacement for traditional endoscopes, but a systematic reconstruction from design philosophy, materials science to manufacturing processes. By eliminating cross-infection, reducing comprehensive costs, and ensuring stable performance, they are reshaping minimally invasive diagnosis and treatment models.

China's disposable endoscopes rely on a complete supply chain system and advanced manufacturing processes, rapidly rising in the global market. We are not only deeply involved but also leverage resource integration and technological innovation to transform this advantage into high-quality, reliable medical solutions that meet international standards.

High-end medical endoscope articulation joints, though formed by laser cutting, derive their true flexibility and reliability from precision processes such as cleaning, polishing, heat treatment, surface treatment, and inspection. It is these meticulous steps that transform the snake bone from 'form' to 'soul', making it a safe and reliable core medical component.