Endoscope Insertion Tube Fatigue Testing: The Cornerstone of Ensuring Clinical Safety and Reliability

December 1, 2025

In the intricate structure of an endoscope, the insertion tube is the core component that directly enters the patient's body and performs the function of bending and exploration. During surgery, it undergoes repeated bending and twisting, and its durability and reliability are directly related to the safety and efficiency of the diagnostic and treatment process. Therefore, fatigue testing of the insertion tube is an indispensable and rigorous quality verification step in the research, development, and production of endoscopes.

The Necessity and Challenges of Fatigue Testing

The working environment of the insertion tube demands extremely high fatigue resistance. If breakage, plastic deformation, or control failure occurs during surgery, the consequences could be dire. Fatigue testing aims to simulate extreme conditions far beyond normal usage cycles to verify its ultimate lifespan and safety margins.

The main challenges include:

Simulating Realism: How to accurately replicate the complex combination of movements in clinical operations (such as torsional loads under U-shaped bending).

Testing Efficiency: The required service life often implies tens of thousands of cycles, so testing must be efficient and capable of running unattended.

Evaluation Criteria: How to quantitatively assess performance degradation rather than relying solely on "whether it breaks" as the judgment basis.

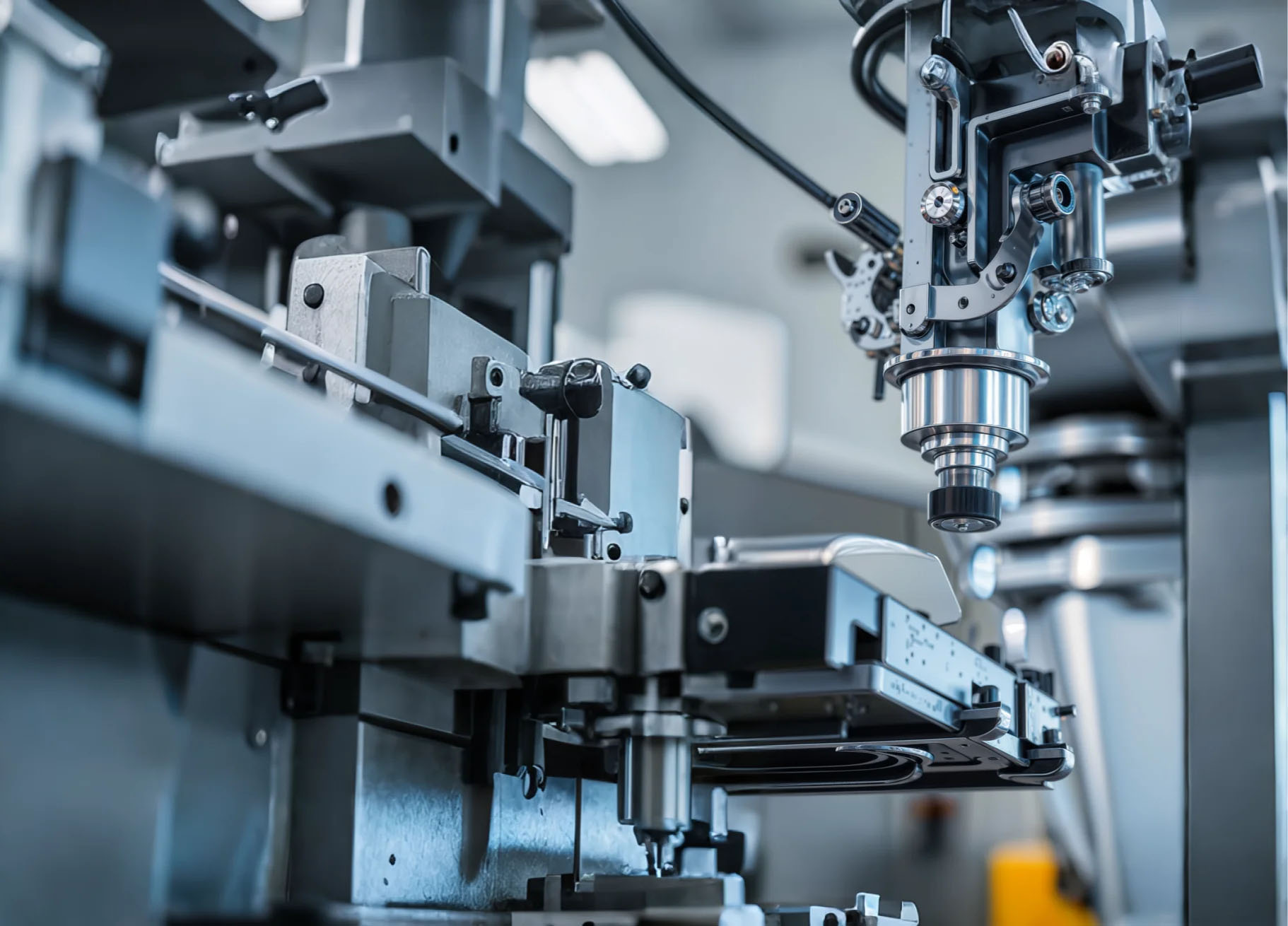

Our Testing System and Methodology

We employ a self-developed multi-axis linkage fatigue testing system, combined with stringent corporate standards (far exceeding industry norms), to conduct comprehensive reliability verification of the insertion tube.

1. Core Testing Items:

Bidirectional Bending Fatigue Test:

Method: Fix the insertion tube to the testing platform and repeatedly bend it to the maximum angle in two opposite directions (e.g., 210° up and down).

Standard: Typically requires passing ≥10,000 continuous cycles without functional failure or visible damage.

Monitoring Points: Post-test bending angle attenuation, whether the outer sheath is damaged, whether the cable is broken, and whether the instrument channel is clear.

Torsional Fatigue Test:

Method: Simulates the rotational motion required when advancing through tortuous anatomical pathways. One end of the insertion tube is fixed, and alternating torque is applied to the other end.

Standard: Requires passing ≥5,000 repeated torsional cycles.

Monitoring Points: Whether internal structures produce abnormal noises, changes in torque values, and whether permanent torsional deformation occurs.

Combined Load Fatigue Test (Advanced Test):

Method: This test most closely simulates real working conditions. While the insertion tube is at its maximum bent state, torsional force and instrument channel patency tests (e.g., repeatedly pushing forceps) are simultaneously applied.

Standard: This test can reveal composite stress failure issues that are undetectable in single tests.

Monitoring Points: Comprehensive performance, particularly operational smoothness and image stability.

2. Features of the Advanced Testing System:

Multi-station Parallel Testing: Improves testing efficiency and ensures consistency verification for mass-produced products.

High-precision Motion Control and Sensing: Precisely controls bending angles and torque while monitoring load changes in real time and plotting fatigue curves.

24/7 Uninterrupted Operation: The equipment is highly reliable and capable of long-term accelerated life testing.

Intelligent Fault Diagnosis: The system automatically records cycle counts and immediately stops and alerts when abnormal torque increases (indicating internal damage) or specimen breakage is detected.

Beyond Pass/Fail: Data-Driven In-Depth Analysis

We are not satisfied with merely "passing the test." The entire testing process generates vast amounts of data, which our engineering team analyzes in depth:

Performance Degradation Curves: Analyze the trend of bending torque changes with increasing cycle counts to predict the tactile feedback of the product after long-term use.

Failure Mode Analysis (FMA): Dissect samples that fail tests to analyze break points and wear patterns, providing feedback to the design team for optimizing material selection, structural design, and processing techniques (such as snake bone riveting and cable anchoring).

Establishing Life Models: Use accelerated life test data to estimate the product's expected lifespan under normal usage conditions, providing clinical references for maintenance and replacement cycles.

Testing Value and Clinical Significance

Rigorous fatigue testing is not only a requirement for quality control but also a responsibility toward patient safety and hospital investment:

Ensuring Patient Safety: Minimizes the risk of medical accidents caused by in vivo instrument failure.

Reducing Hospital Costs: Significantly decreases high repair costs and the risk of surgical interruptions due to instrument damage.

Maintaining Brand Reputation: Reliable products mean longer service life and more stable operational feel, directly enhancing doctors' trust in the brand.

Driving Product Innovation: Test data is the most valuable asset for driving iterative optimization of insertion tube materials and structural design.

Conclusion

Fatigue testing of the endoscope insertion tube is the rigorous science behind exceptional products. It represents the depth of a manufacturer's commitment to the term "reliability." By building a scientific testing system, implementing standards higher than industry norms, and adhering to data-driven in-depth analysis, we ensure that every endoscope leaving the factory possesses the durability to meet the stringent challenges of clinical use, providing lasting, safe, and trustworthy support for doctors and patients.