±0.02mm

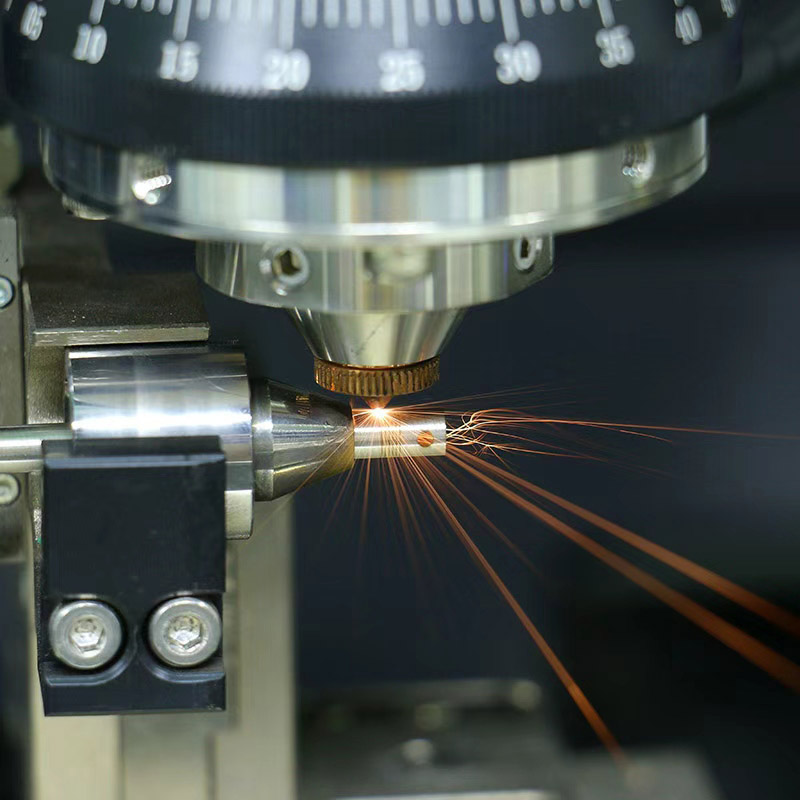

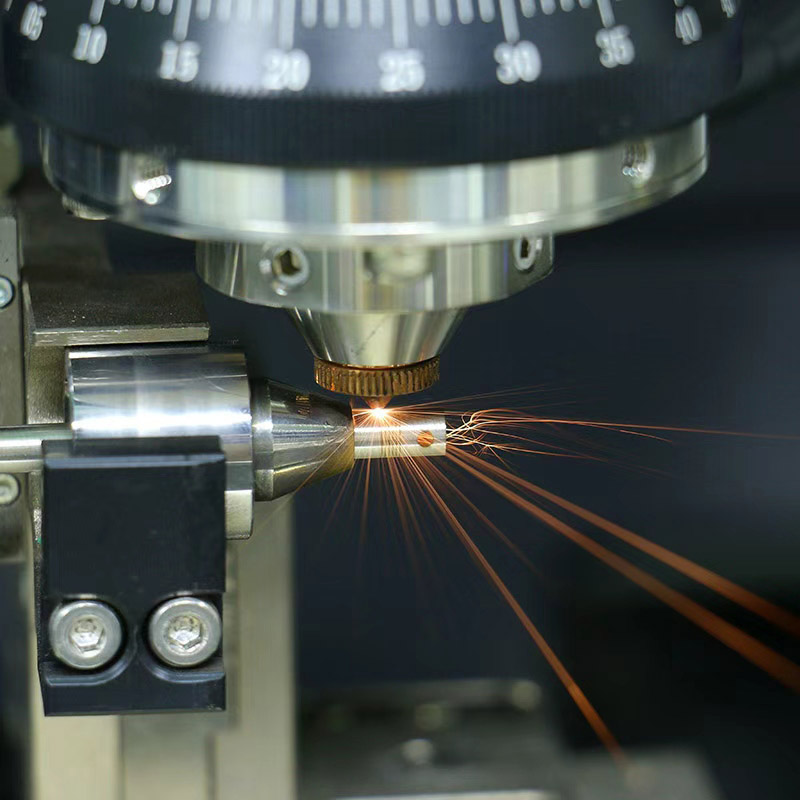

±0.02mm High-Precision Laser Cutting

High-precision cutting of φ0.3–φ15mm tubes; cutting accuracy ±0.02mm, complex cuts can be achieved precisely. Premium laser source and stable transmission ensure reliable continuous operation.

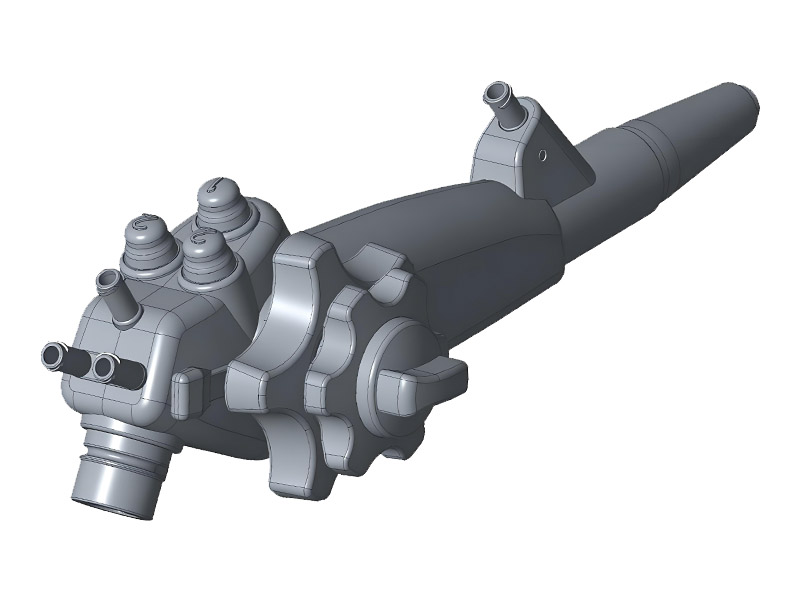

Precision Craftsmanship for Medical Excellence

±0.02mm

±0.02mm High-precision cutting of φ0.3–φ15mm tubes; cutting accuracy ±0.02mm, complex cuts can be achieved precisely. Premium laser source and stable transmission ensure reliable continuous operation.

±0.02mm

±0.02mm Automated high-precision riveting, minimum snake bone φ1.8mm; riveting accuracy ≤ ±0.02mm, strong connections with flexible movement.

Weld ≥0.1mm

Weld ≥0.1mm Precision welding with weld diameter as small as 0.1mm; inert gas protection prevents oxidation. Passes high/low temperature and vibration tests without cracking or detachment, ensuring excellent reliability.

Deviation ≤0.01mm

Deviation ≤0.01mm Self-developed automated equipment achieves high-precision welding; camera to PCB deviation ≤0.01mm. Laser welding minimizes heat impact, with real-time visual quality monitoring.

+0.5℃

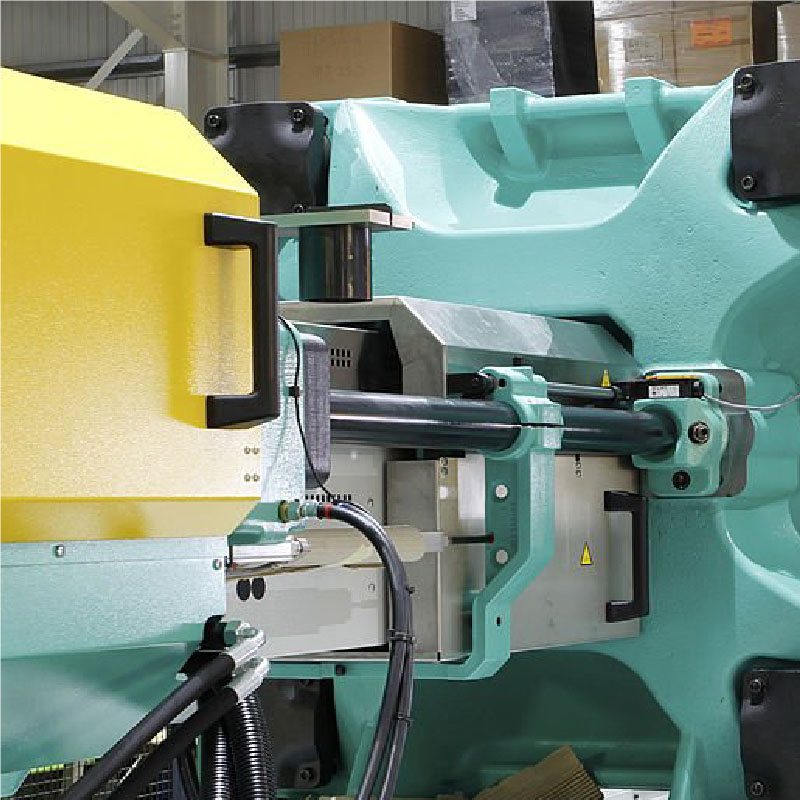

+0.5℃ Design and manufacturing capabilities; advanced injection molding and tooling, smooth surface without bubbles or sink marks; automatic feeding, demolding, and inspection ensure efficiency and consistent quality.

φ0.5–φ15mm

φ0.5–φ15mm Precision extrusion of φ0.5–φ15mm tubes with coating thickness 0.05–0.5mm; high-precision die and temperature control ensure uniform, dense coating with strong adhesion.

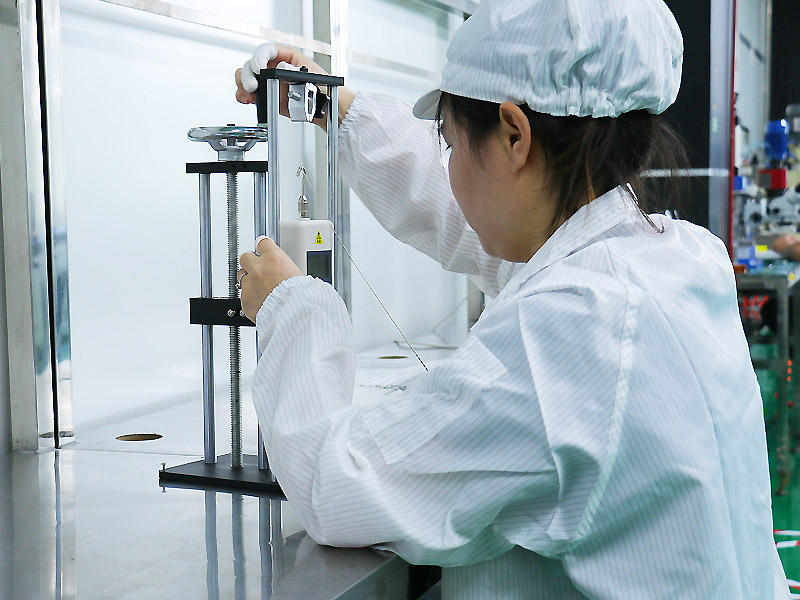

100% Inspected

100% Inspected Comprehensive inspection system covering raw materials, processes, and finished products; equipped with high-precision instruments and automated devices to ensure quality control and data traceability.

Risk Mitigation

Risk Mitigation Focus on core endoscope technology, mastering the complete process chain; integrates clinical use scenarios to identify and mitigate design risks in advance.

Self-Developed

Self-Developed In-house developed laser cutting, camera welding, visual inspection, fatigue and durability testing equipment to ensure quality and production capacity.