Subversion and Innovation: The Technical Core and Future Prospects of Disposable Endoscopes

December 1, 2025

In the field of minimally invasive medicine, a silent revolution is underway. The risks of cross-contamination, high cleaning and disinfection costs, and equipment wear and tear associated with traditional reusable endoscopes are being overturned by an innovative solution—the single-use endoscope. It is not simply a "disposable" version of reusable endoscopes but represents a comprehensive paradigm shift in design philosophy, materials science, and manufacturing. This article delves into the core logic and craftsmanship behind this innovative technology.

I. The Origin: Addressing Core Clinical Pain Points

The rise of single-use endoscopes is rooted in a deep understanding of three major clinical pain points:

Complete Elimination of Cross-Contamination: Traditional endoscopes have complex structures and numerous channels, making cleaning and disinfection extremely difficult and posing significant risks for hospital-acquired infections. Single-use endoscopes fundamentally cut off this transmission route, providing ultimate safety for patients.

Significant Reduction in Overall Costs: While the unit price may seem costly, when considering the expensive purchase fees, maintenance costs, dedicated personnel cleaning expenses, disinfection consumable costs, and downtime losses due to malfunction repairs, the comprehensive economic benefits of single-use solutions become highly attractive in certain clinical scenarios.

Consistent Performance: Each use involves a brand-new, undamaged device. This avoids performance degradation issues such as lens scratches, light attenuation, channel wear, and joint loosening caused by long-term use of reusable endoscopes, ensuring the clearest and most reliable images and operational feel for every examination.

II. Technical Core: Not "Simplification," but "Reconstruction"

Designing a high-performance, low-cost, and reliable single-use endoscope presents far greater technical challenges than traditional endoscopes. It requires achieving extreme optimization and integration of functions under cost constraints.

Innovations in Optical Systems:

Chip-on-Tip Technology: This is the core technology of single-use endoscopes. Miniature CMOS image sensors are directly encapsulated at the tip of the insertion section, enabling front-end photoelectric conversion. This eliminates the expensive and fragile image transmission bundles in traditional endoscopes, with signals transmitted digitally through slender wires, not only significantly reducing costs but also achieving grid-free, clearer image quality.

High-Performance LED Lighting: Miniature LEDs are integrated at the lens tip as light sources, replacing traditional bulky external xenon light sources and fiber optic light guides, further simplifying the structure and reducing costs.

Materials Science and Precision Injection Molding:

Medical-Grade Polymer Materials: The insertion section shell is typically made of highly flexible, biocompatible medical-grade TPU (thermoplastic polyurethane) or PEBAX (polyether block amide) materials, ensuring flexibility and safety through precision extrusion molding.

Disposable Precision Components: Handles and operational parts are no longer made of metal but are engineered plastic components manufactured through ultra-high-precision injection molding technology. These parts must achieve strength, gear transmission accuracy, and operational feel comparable to metal components at extremely low costs, placing extreme demands on mold design and injection molding processes.

Highly Integrated Design:

Structures such as suction/water delivery channels, instrument channels, and steel wires are integrated in the most streamlined and efficient manner within a minimal space. All components are optimized for single-use, focusing on core functions and eliminating all redundancies.

Miniaturization and Integration of Electronic Systems:

Image processing, power management, and other electronic units are highly integrated into a miniaturized camera control module (CCU) or directly into the handle, enabling plug-and-play functionality without complex adjustments or calibration.

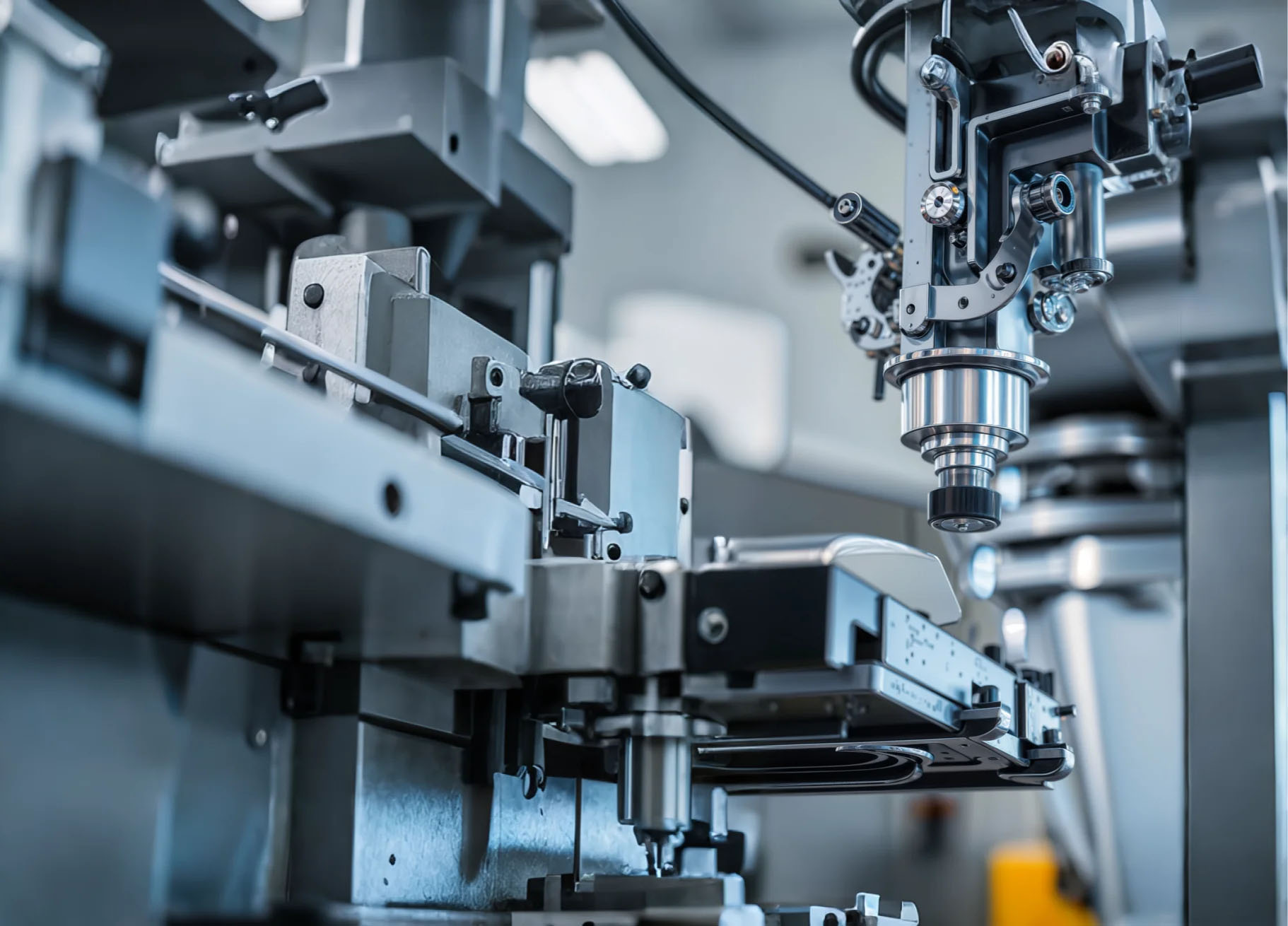

III. Manufacturing: The Pursuit of Scale and Automation

The commercial success of single-use endoscopes heavily relies on scalable, automated, and low-cost manufacturing capabilities.

Automated Assembly Lines: Due to the massive production volume (in the millions), almost all production steps—from sensor mounting, lens focusing, cable crimping, to final assembly and testing—must be completed on highly automated production lines to ensure consistency and efficiency while minimizing human error.

Stringent Cost Control: Every aspect, from supply chain management to production rhythm optimization, requires value engineering analysis to precisely control costs down to the last cent while ensuring performance and reliability.

100% Functional Testing: Despite being single-use products, each endoscope must undergo automated rapid testing for air tightness, water flow patency, image clarity, color reproduction, light brightness, and button functionality before leaving the factory, ensuring a 100% yield rate.

IV. Application Scenarios and Future Prospects

Currently, single-use endoscopes are widely used in high-risk infection and difficult-to-clean areas such as respiratory departments (bronchoscopes), digestive departments (duodenoscopes, choledochoscopes), and urology departments (ureteroscopes).

In the future, as technology matures further and costs continue to decline, their application scope will expand to more departments. Meanwhile, integration with AI-assisted diagnostics will become the next breakthrough—embedding AI algorithms into the imaging end of single-use endoscopes can enable real-time lesion identification, measurement, and diagnostic prompts, perfectly combining "disposable" hardware with "smarter over time" software, reshaping clinical diagnosis and treatment pathways.

Conclusion

Single-use endoscopes represent not just a new product but a new way of thinking and a new model. Through disruptive technological reconstruction and manufacturing innovation, they reduce infection risks to zero, simplify clinical operations, and make medical resource allocation more efficient.

We stand at the forefront of this transformation. By delving deep into materials science, microelectronics, precision manufacturing, and automation technology, we are committed to developing single-use endoscope products that are not only "affordable" but also "highly usable," providing safer, more economical, and more convenient minimally invasive diagnosis and treatment solutions for global medical institutions. Let innovative technology benefit every medical professional and patient.