The Art of Precision: Post-Processing Technologies for Endoscope Snake Bone Components

December 1, 2025

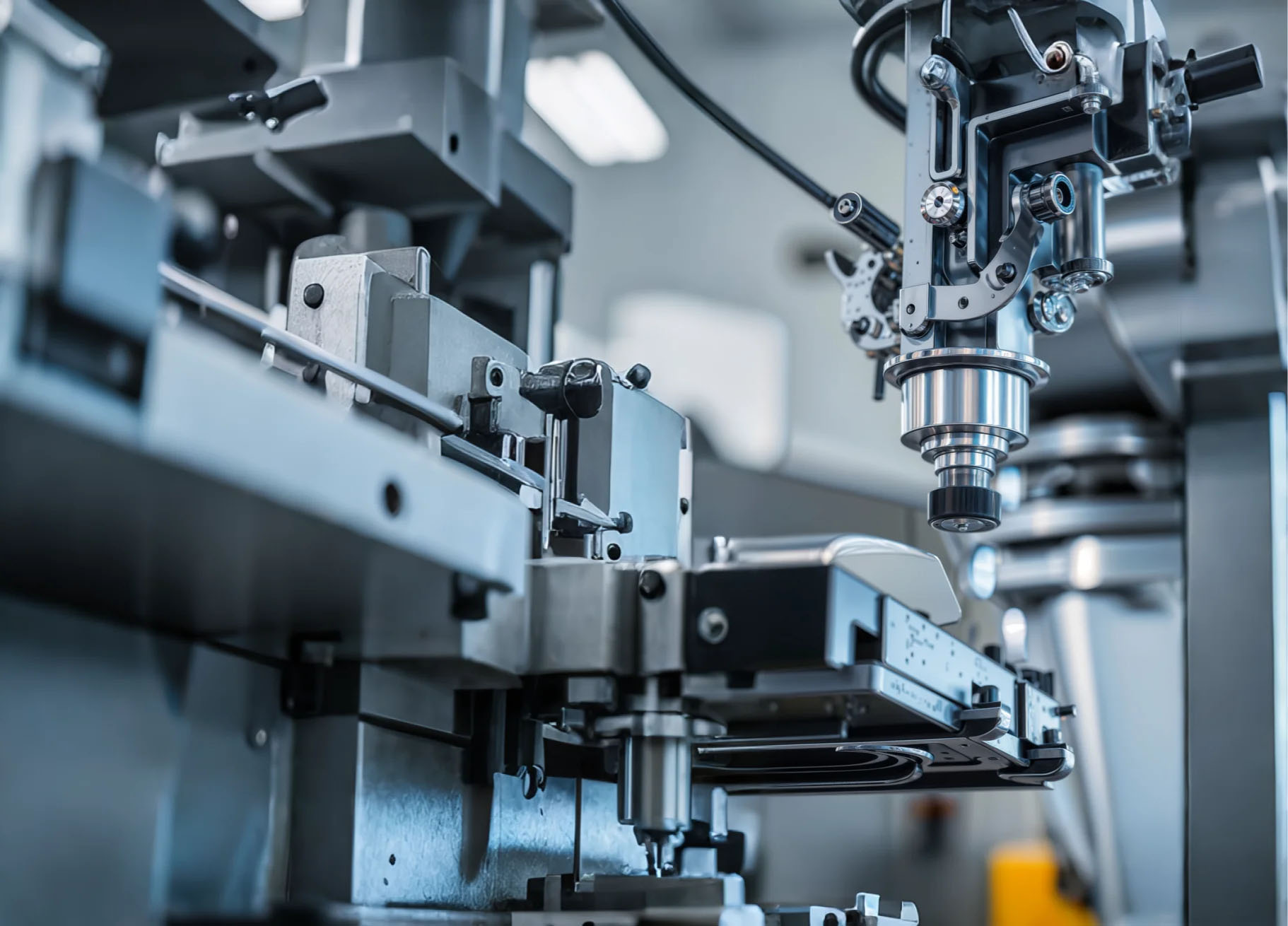

In the core of high-end medical flexible endoscopes—the insertion tube—the articulation joint component is the key structure that enables flexible steering and precise positioning. Utilizing high-precision laser cutting technology, we engrave complex and regular grid patterns onto the tubing, granting it omnidirectional bending capabilities. However, laser cutting is merely the beginning of the manufacturing process. Each segment of the articulation joint must undergo a series of extremely precise and stringent post-processing steps to transform into a safe, reliable core component that meets medical standards. This article will provide an in-depth analysis of this meticulous "transformation from cocoon to butterfly" process.

1. Cleaning: Removing All Processing Residues

Laser cutting inevitably produces heat-affected zones, slag, and tiny metal particle residues. If not removed, these contaminants can directly affect subsequent processes and potentially lead to product failure.

Process Purpose: Thoroughly remove oil stains, metal dust, slag, and oxides from both inner and outer surfaces.

Technical Method: Multi-tank ultrasonic cleaning combined with specialized chemical cleaning agents. By setting different frequencies of ultrasonic cavitation, the complex grid structure's inner and outer surfaces are thoroughly blasted and cleaned without dead angles. This is followed by multi-stage pure water rinsing and IPA (isopropyl alcohol) dehydration to ensure absolute surface cleanliness.

Quality Requirements: Performed in a cleanroom environment; post-cleaning, the workpiece surface must pass microscopic inspection and residue-free testing.

2. Deburring and Polishing: Creating a Smooth and Safe Surface

Laser-cut sections have micron-level burrs and sharp edges. During the repeated bending of an endoscope, these burrs may detach and become metal debris or wear down internal precision instruments and cables, posing significant safety risks.

Process Purpose: Smooth cutting edges, remove all microscopic burrs, and achieve a smooth, burr-free surface without sharp angles.

Technical Methods:

Mechanical Polishing: For outer surfaces, processes such as micro-particle sandblasting or magnetic abrasive finishing are used for overall polishing.

Chemical Polishing (Electropolishing): This is a more advanced and efficient method. The workpiece acts as an anode in a specific electrolyte solution, where electrochemical dissolution preferentially removes microscopic protrusions and sharp edges, achieving uniform global polishing. This not only removes burrs but also forms a dense passivation film, enhancing corrosion resistance.

Quality Requirements: Smooth surface, rounded edges, no visible burrs under magnification, and passing a "gauze test" to ensure no fiber snagging.

3. Heat Treatment (Stress Relief Annealing): Restoring the Material's Flexible Nature

The high energy input from laser cutting creates concentrated stress and work hardening within the material, leading to increased brittleness and significantly reduced fatigue life. Without stress relief, the articulation joint is highly prone to fracture during bending.

Process Purpose: Eliminate internal stress, restore the material's toughness and fatigue strength, and ensure the articulation joint can withstand hundreds of thousands of repeated bending cycles.

Technical Method: Precision annealing in a vacuum or protective atmosphere (e.g., argon) furnace. By precisely controlling the heating curve, holding temperature, and cooling rate, the material's crystal structure is rearranged, and internal stress is fully relieved without altering other physical properties.

Quality Requirements: Post-treatment, the material must maintain specified hardness and tensile strength while passing fatigue tests to verify its lifespan.

4. Surface Treatment and Coating (Optional)

Depending on design requirements, special surface treatments may be applied to the articulation joint to enhance its performance.

Passivation: For stainless steel materials, nitric acid or citric acid passivation solutions are used to form a very thin chromium oxide protective film on the surface, significantly enhancing resistance to chemical corrosion and oxidation.

Coating: Spraying low-friction coatings such as Teflon (PTFE) can significantly reduce friction between the articulation joint and the external sheath, making endoscope insertion smoother and improving operational feel.

5. Comprehensive Quality Inspection and Verification

Every processed articulation joint segment must undergo rigorous inspection to ensure absolute reliability.

Dimensional Accuracy Inspection: Using optical projectors or 3D video measuring systems to verify key dimensions such as pitch, line width, and cutting angles, ensuring complete consistency with design drawings.

Surface Quality Inspection: 100% visual inspection under high-magnification microscopes to confirm no cracks, burrs, or contamination.

Performance Testing:

Bend Testing: Simulating actual working conditions with specialized fixtures to perform repeated bending tests, verifying flexibility, consistency, and fatigue life.

Flexibility Testing: Measuring bending radius and recovery.

Cleanliness and Biocompatibility Verification: Ensuring all cleaning steps are effective and the final product meets ISO 10993 biocompatibility standards.

Conclusion

Laser cutting defines the form of the articulation joint, while post-processing imbues it with soul and quality. From cleaning and deburring to stress relief annealing, each step embodies the relentless pursuit of precision, safety, and reliability. It is these seemingly minor yet crucial post-processing steps that ensure every endoscope can perform its diagnostic and therapeutic missions flexibly, reliably, and resiliently within the complex environment of the human body.

We deeply understand that outstanding performance stems from uncompromising attention to every detail. This is the core of our manufacturing philosophy and the foundation of your trust.