Endoscopic Snake Bone Riveting Technology: The Core Process of Precision Motion Control

December 1, 2025

In the field of modern flexible endoscope manufacturing, the snake bone structure is a key component that enables precise bending of the instrument's distal end. The quality of the snake bone riveting process directly determines the operational performance, service life, and safety of the endoscope. This article will delve into the technical aspects and current developments of this precision manufacturing process.

Importance of Snake Bone Structure and Process Challenges

The snake bone assembly serves as the "spine" of the endoscope, responsible for transmitting operational forces and enabling multi-angle bending. Its manufacturing process faces numerous challenges:

Miniaturization requirements: Individual joint dimensions are typically only 1-3mm, requiring extremely high riveting precision.

Material compatibility: Must account for the properties of metal materials such as stainless steel and titanium alloys.

Motion reliability: Must ensure flexibility and stability even after tens of thousands of bending cycles.

Biocompatibility: All components must meet medical-grade cleanliness and biocompatibility standards.

High-Precision Riveting Process Technology

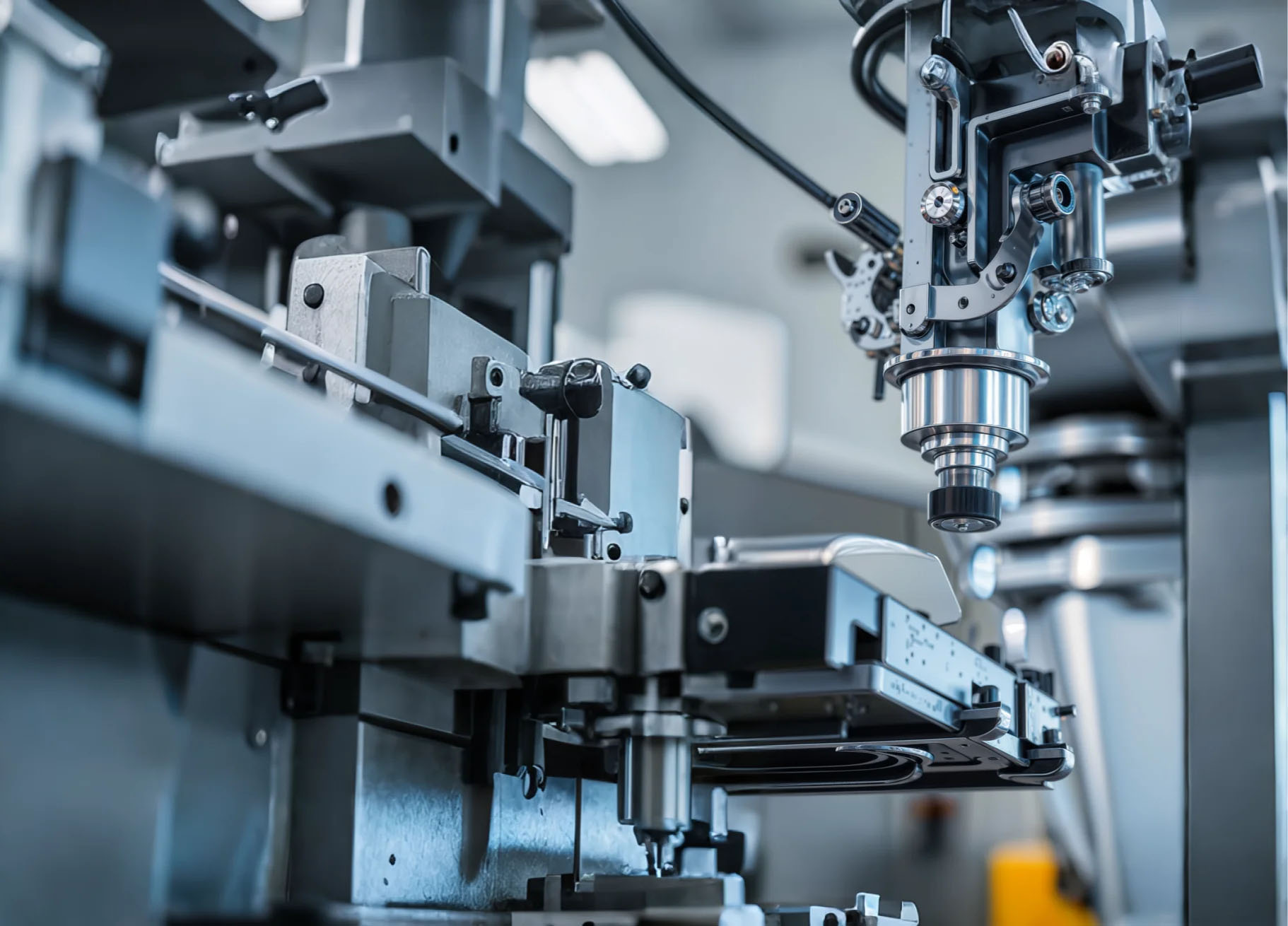

Multi-Station Precision Riveting System

We utilize a self-developed multi-station automatic riveting system that achieves:

Riveting precision of ±0.01mm

Daily production capacity exceeding 2,000 joint assemblies

Pressure control accuracy of 0.1N

Specialized Rivet Design and Manufacturing

To meet the specific needs of endoscopes, we have developed a series of specialized micro rivets:

Diameter range: 0.3-0.8mm

Optimized head design to reduce motion friction

Surface smoothness Ra ≤ 0.2μm

Special annealing treatment to eliminate internal stress

Quality Control and Inspection System

Process Monitoring System

Machine vision for real-time monitoring of riveting positions

Pressure sensor feedback for controlling riveting force

Automatic recording of process parameters for each riveting point

Full-Size Inspection Items

Dimensional accuracy inspection: Using optical 3D measurement systems

Motion performance testing: Simulating actual usage conditions with thousands of bending tests

Strength testing: Measuring tensile strength and fatigue life

Surface quality inspection: Examining surface defects under an electron microscope

Technological Innovations and Breakthroughs

Laser Micro-Riveting Technology

To meet the demands of ultra-thin endoscopes, we have developed a laser micro-riveting process:

Non-contact processing avoids mechanical stress

Heat-affected zone controlled within 50μm

Particularly suitable for ultra-thin snake bones with diameters less than 2mm

Intelligent Process Optimization System

Based on big data and machine learning algorithms, we have established a process parameter optimization system:

Real-time analysis of riveting quality data

Automatic adjustment of process parameters

Prediction of equipment maintenance needs

Application Value and Clinical Significance

Precision riveting technology significantly enhances endoscope performance:

Improved operational flexibility: Bending angles can reach 180°-210°

Extended service life: Mean time between failures increased by 30%

Enhanced surgical precision: More accurate and timely operational response

Reduced maintenance costs: Modular design facilitates quick replacements

Future Development Directions

As endoscope technology continues to advance, snake bone riveting processes will evolve in the following directions:

Further miniaturization to accommodate thinner endoscope requirements

Development of new composite material joining processes

Achievement of fully automated intelligent manufacturing

Integration of real-time quality monitoring and feedback systems

Conclusion

As a critical process in endoscope manufacturing, snake bone riveting directly impacts the performance and reliability of medical devices. Through continuous technological innovation and process optimization, we provide medical device manufacturers with high-precision, high-efficiency riveting solutions, supporting the advancement of minimally invasive medical technology and offering patients safer, more effective diagnostic and therapeutic services.