Disposable Endoscope Sheath

Different material solutions and processing techniques to meet your needs for various scenarios

Features

- Customization capability

- High cost-effectiveness

- Stable and mature process

- Reliable delivery

Quality guaranteed

Our material formulations ensure adjustable softness and hardness; our processes significantly reduce surface friction coefficient; our testing guarantees material biocompatibility

- More info

Product Overview:

While ensuring product performance, we have improved the production process to achieve efficient manufacturing and ensure product stability. Customization of various materials and different specifications is supported.

Structure Introduction:

Outer Sheath

Material: Standard TPU, PVC, PE, or TPE.

Structural Reinforcement Layer

Material: Engineering plastic monofilament (such as PEEK, PET), synthetic fiber, or low-cost metal wire.

Liner and Channel

Material: High-density polyethylene (HDPE), polypropylene (PP), or low-cost PTFE.

Process Introduction:

Co-extrusion

Simultaneously extruding the outer sheath material and inner channel material to form a single composite tube with multiple lumens in one step.

Advantage: The friction coefficient meets requirements, achieving a balance between functionality and economy.

Simplified Reinforcement

Using plastic reinforcement filaments directly woven.

Integrated Injection Molding

Instead of using metal machined parts for hose end connectors, the fittings are directly molded onto the hose ends through precision injection molding. Multiple parts are integrated into one, greatly reducing assembly steps and the number of components.

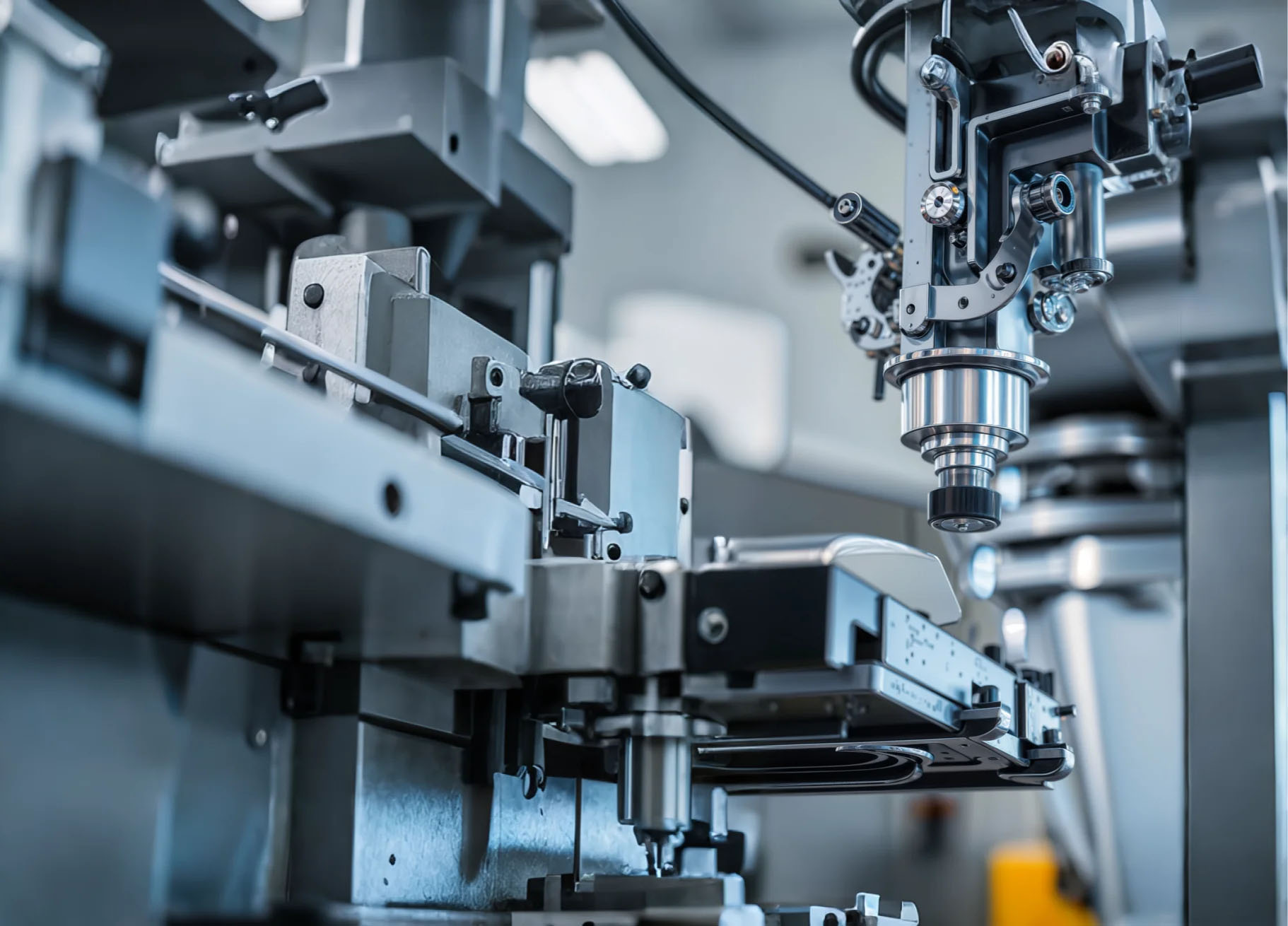

Automated Assembly & Testing

The entire production line is designed for high automation, minimizing manual intervention.

Most tests are fully automated online tests (such as airtightness on-off testing), with fast speed and stable product performance.