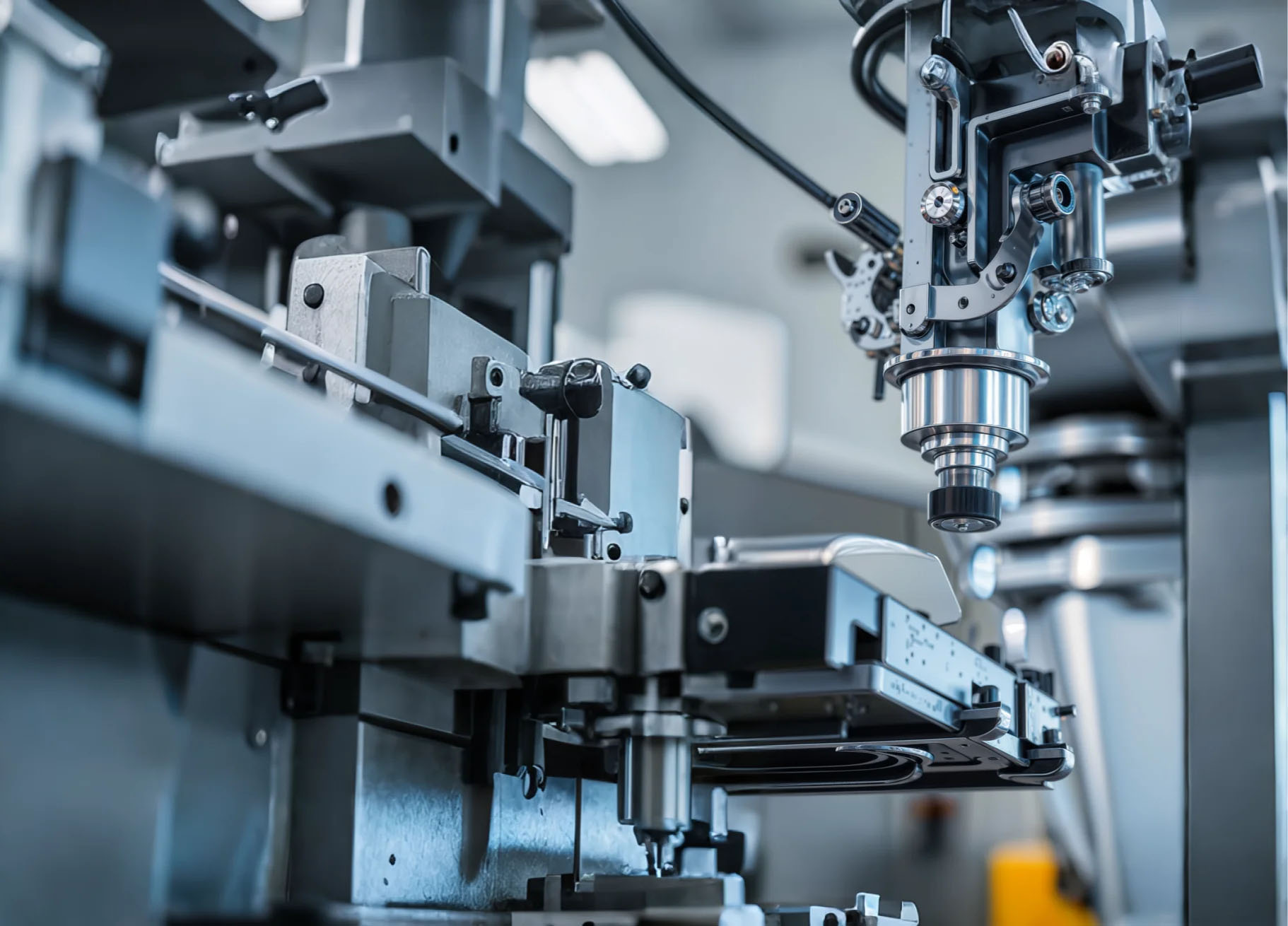

Endoscope Insertion Section Outer Sheath

Different material solutions and processing techniques to meet your needs for various scenarios

Features

- Customization capability

- High cost-effectiveness

- Stable and mature process

- Reliable delivery

Quality guaranteed

Our material formulations ensure adjustable softness and hardness; our processes significantly reduce surface friction coefficient; our testing guarantees material biocompatibility

- More info

Product Overview: The outer cover/insertion tube sheath of a medical endoscope is the outermost protective structure of the insertion section. It comes into direct contact with human tissues and therefore must meet extremely stringent requirements: biocompatibility, flexibility, wear resistance, chemical resistance (to disinfectants and bodily fluids), low friction coefficient, waterproof sealing, etc.

Product Structure: Inner liner; middle reinforcement layer; outer cover layer

Specifications: Outer diameter, length, and wall thickness can all be customized

Inner Liner:

Function: Primarily forms a smooth channel to protect the internal instrument bundles and serves as the base for the braiding layer.

Materials: PTFE, PI, TPU, PA, PEBAX, PEEK, etc.

Process: Precision extrusion molding

Middle Reinforcement Layer (Braiding / Mesh Layer):

Function: This is the "skeleton" of the sheath, embedded between the outer layer and the inner liner. It determines the sheath's compression resistance, torsion resistance (prevents kinking), and push force transmission efficiency.

Materials: Stainless steel 304, Tungsten, etc.

Process Overview:

1. Stainless Steel Coil Reinforcement

Process: Extremely fine medical-grade (e.g., 304 or 316L) stainless steel wire is tightly wound in a spiral pattern around the inner liner tube. The pitch between coils can be adjusted to balance flexibility and rigidity.

Advantages: Provides excellent crush resistance while allowing the channel to bend extremely without jamming. When bent, the coil spacing increases on one side and decreases on the other, offering great flexibility.

Applications: This is currently the most mainstream and efficient reinforcement method, widely used in endoscopes from major brands.

2. Stainless Steel Braid Reinforcement

Process: Similar to the reinforcement layer of the outer cover sheath, a mesh tube is braided from stainless steel wire and sleeved over the inner liner tube.

Advantages: Provides good overall strength, including compression and torsion resistance.

Disadvantages: Under extreme bending, the mesh wires may experience slight mutual shearing, potentially resulting in less smooth handling and minor noise compared to coil reinforcement.

Applications: Also a common solution, sometimes used in combination with coils.

3. Hypotube

Process: Uses an extremely thin stainless steel tube with complex patterns (e.g., zigzag, spiral) laser-cut into the tube wall.

Advantages: Provides unparalleled push force and radial support, with the best maintenance of channel inner diameter.

Disadvantages: Poor flexibility, making it difficult to use in insertion sections requiring large bending ranges.

Applications: Mainly used in rigid endoscopes or non-bending rigid parts of flexible endoscopes (e.g., the section connecting to the control unit).

Outer Cover / Jacket:

Function: This is the outermost protective layer, directly determining the tactile feel, friction coefficient, and durability.

Materials: Nylon, TPU, PEBAX, PEEK, etc.

Process: Precision extrusion; hydrophilic coating

Manufacturing Process

Mandrel Preparation: A metal rod with a diameter precisely equal to the channel's inner diameter.

Extrude Inner Liner: Materials like PTFE or PFA are evenly extruded over the mandrel via an extruder to form a smooth inner wall.

Coil Winding: On a precision CNC winding machine, stainless steel wire is tightly wound around the inner liner tube at a preset pitch and tension.

Extrude Outer Layer: The assembly is fed into the extruder again, where a fluoropolymer outer skin is co-extruded over the coil. The molten polymer flows into the gaps between coils, cooling to firmly bond all components into a single unit.

Remove Mandrel: After cooling and setting, the mandrel is withdrawn from the tube.

Post-Processing: Cut to the required length, with precision treatment of the ends (e.g., polishing, installing metal rings) to ensure smooth transition at the instrument port connection, free of any burrs that could snag instruments or gloves.

Strict Testing:

Leak Test: Ensures channel airtightness to prevent leakage during irrigation.

Push Force Test: Measures the force required to push specific instruments through the channel, ensuring the handling feel meets requirements.

Abrasion Test: Simulates repeated instrument passage to检验通道寿命。

Chemical Resistance Test: Soaking in disinfectant solutions to evaluate aging performance.

Bend Test: Simulates endoscope bending to ensure the channel does not collapse or experience sudden resistance increases.